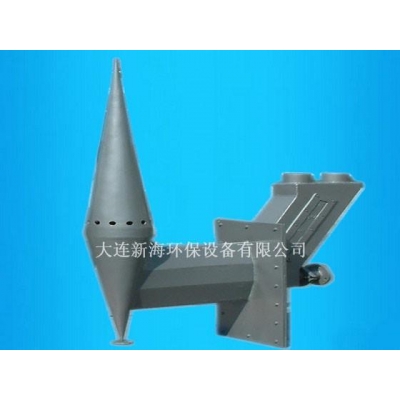

The VRI reactor is mainly used in smelter gas scrubbing system. Its function is to jet out alumina evenly into the gas reaction device for completing chemical reaction and adsorption reaction with hydrogen fluoride gas (HF) in the smelter gas and transform the HF gas into solid form and then collect the reactant into bag filter, so that recycling material and scrubbing the harmful gas from smelter can be achieved.

The VRI reactor manufactured by our company has the characteristics of small size and high adsorption efficiency, etc. Its double-cone shape can reduce the equipment resistance and make the alumina jetting out in a butterfly-like film which will increase the adsorption area and efficiency. The jetting orifice is installed with alloyed wear resistant bushing which can prolong its lifespan by five times. The fluidization component is made by stainless steel sintered felt after pressing which has a delicate configuration and unnecessary for maintenance in general. The material jetting orifice is thermal-treated which enhanced its wear resistance. The charging bin is equipped with inspection window which facilitates operation and maintenance. The smooth fluidization component could improve the efficiency. The air inlet pipe is changed as flange connection so that it has a good sealing performance. Anyway, it is an ideal reaction device at present.